Cavitation

During a Transient Analysis, if the gauge pressure, P, of the fluid declines to its vapor pressure limit, P0 , then vapor will begin to form and the vapor volume will expand at all such computation points as long as P0 persists. In fact, as the pressure approaches P0 , air will be released from solution and the wave speed will decrease; this behavior can be simulated in HAMMER using the wave speed reduction factor.

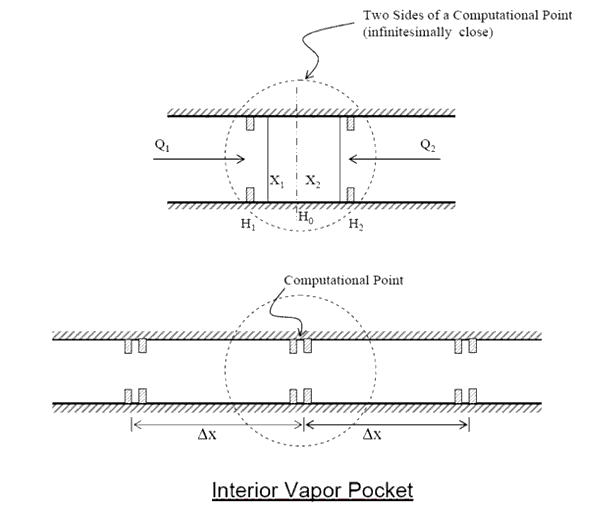

For simplicity, let us focus on an interior point of a pipe. With the inclusion of friction, there are three unknowns at each time step for every interior point in single-phase flow: two heads and a discharge. In fact, in order to track the vapor volume(s), Xi , i = 1, 2, that may form, additional variables are required to record such volumes. There are two fundamental hypotheses invoked in treating vapor pockets:

Although these hypotheses are not entirely valid - on physical and logical grounds - it turns out that it is difficult if not impossible to proceed without them and that they allow us to predict the system behavior remarkably well (Provoost, 1976). By virtue of these assumptions, there is no flow across a pocket and the interface between the vapor and liquid remains fixed in space.

Solution

It is convenient to conceptualize each interior point as being comprised of two conjugate points infinitesimally close to each other as shown in the Interior Vapor Pocket figure below. To solve for the unknowns at the interior point, there are two distinct regimes based on whether a vapor pocket has formed:

(i) Pressure Exceeds Vapor Pressure (P > P0)

The single-phase fluid is described by two characteristic equations, two head-loss equations, continuity, and zero vapor volumes. Thus, one can solve for the heads, Hi and H, flows, Qi , where i = 1, 2 and Qi is the inflow towards the point from the ith branch.

Because of continuity, Q1 = - Q2.

(ii) Pressure Equals Vapor Pressure (P = P0)

In this case, consider the head, H, in the "middle" of the point is H0 = P0 + Z, where Z is the elevation of the point. In addition, there are still two characteristic equations, two head-loss equations and the continuity relations, with the latter being as follows:

dXi / dt = - Qi

In summary, in both modes, there are seven variables - H, Hi , Qi and Xi - and seven equations. Transitions between these two states may occur multiple times during a simulation. It is also physically possible that a vapor pocket both opens and closes, or vice-versa, within a single (and arbitrary) time step. There is logic in the transient solver to detect this occurrence and deal with it. HAMMER traces the evolution of the vapor pockets and records the maximum volume attained at each point during the simulation.

The localization of vapor pockets to points is merely a convenient conceptualization which is logically and physically impossible. Nevertheless, for volumes which are smaller than those occupied by the pipeline between adjacent calculation points, the simulation is quite robust. However, the program neither adjusts its method of calculation (e.g., by limiting the size of pockets or transferring excess volumes to adjacent points) nor prints warning/error messages should the vapor volumes grow large enough to fill the pipe segment between two computation points. The user must pay attention to this limitation of the program.